- Home

- crown gear

- PDF] DESIGN AND ANALYSIS OF CROWN PINION OF A DIFFERENTIAL GEAR BOX FOR REDUCED NUMBER OF TEETH TO IMPROVE TORQUE TRANSMITTED

PDF] DESIGN AND ANALYSIS OF CROWN PINION OF A DIFFERENTIAL GEAR BOX FOR REDUCED NUMBER OF TEETH TO IMPROVE TORQUE TRANSMITTED

4.8 (312) · $ 8.50 · In stock

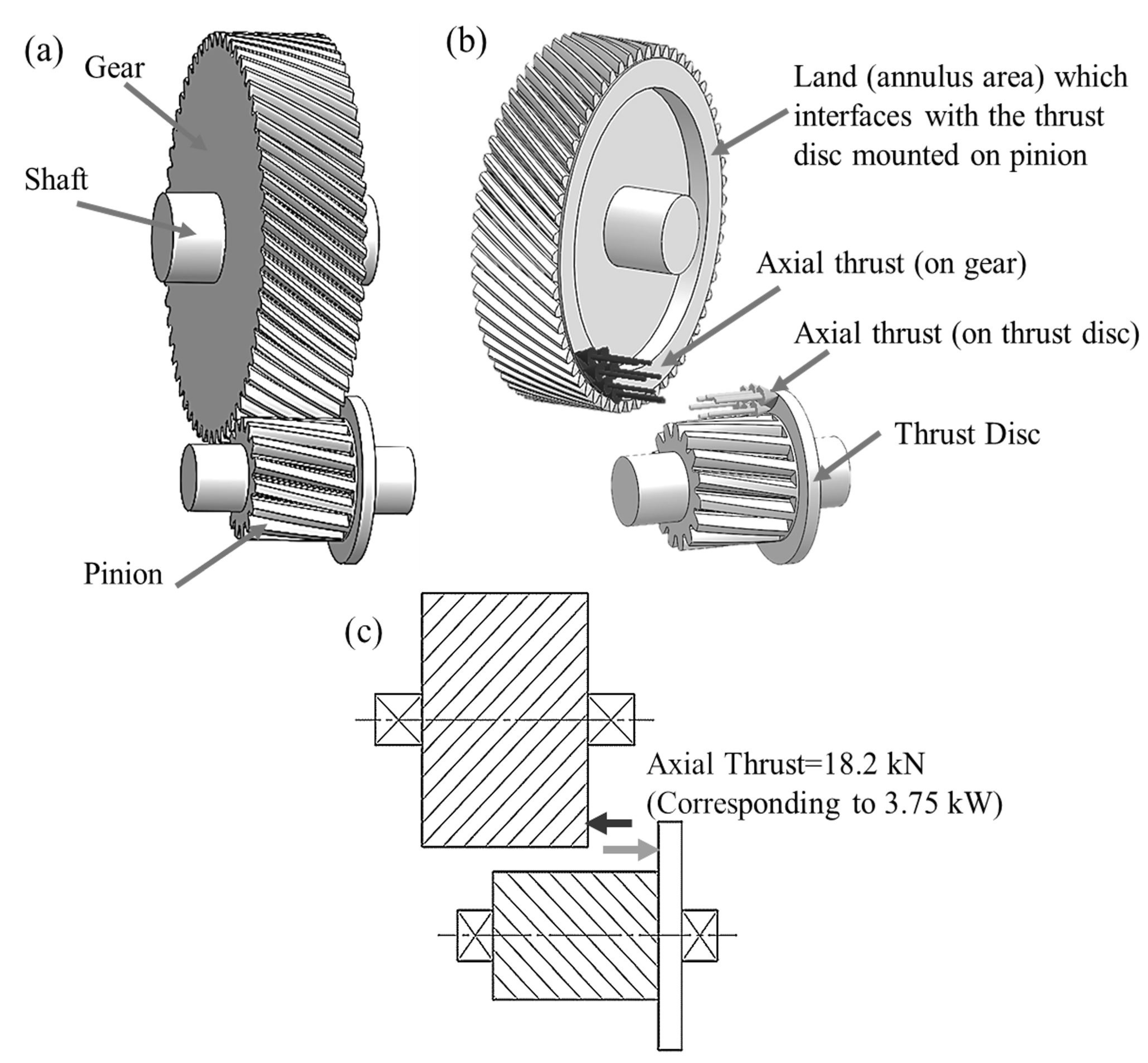

Bevel gears are widely used because of their suitability towards transferring power between nonparallel shafts at almost any angle or speed. Spiral bevel gears, in comparison to straight or zerol bevel gears, have additional overlapping tooth action which creates a smoother gear mesh. This smooth transmission of power along the gear teeth helps to reduce noise and vibration that increases exponentially at higher speeds. Currently the bolero pickup vehicle of Mahindra Company is running with a pinion present in the differential gear box having 11 numbers of teeth. By reducing number of teeth on pinion, we can increase the torque. So we carried out this work to design a new pinion suitable to fit in the bolero pickup vehicle. Only the number of teeth are reduced by keeping all other dimensions same to fit the new pinion in the same housing.

Design and assembly analysis of a gear train of a gear box report

Applied Sciences, Free Full-Text

PDF) Design and Analysis of Crown Pinion of a Differential Gear Box for Reduced Number of Teeth to Improve Torque Transmitted

Types of Gears KHK Gear Manufacturer

Applied Sciences, Free Full-Text

Experimental investigation of high carbon steel MMC for crown pinion gear - ScienceDirect

PDF) Design and Analysis of Crown Pinion of a Differential Gear Box for Reduced Number of Teeth to Improve Torque Transmitted

Applied Sciences, Free Full-Text

Optimization of crown and pinion using metal matrix composite - ScienceDirect

PDF) Pinion Failure Analysis of a Helical Reduction Gearbox in a Kraft Process

Applied Sciences, Free Full-Text

![PDF] DESIGN AND ANALYSIS OF CROWN PINION OF A DIFFERENTIAL GEAR BOX FOR REDUCED NUMBER OF TEETH TO IMPROVE TORQUE TRANSMITTED](https://d3i71xaburhd42.cloudfront.net/57effcf4bde7c14c7d744c1682299fbaf1e03f41/2-Figure1-1.png)