Hot Crimping for Joining Magnet Wires, 2012-04-02

4.9 (287) · $ 25.50 · In stock

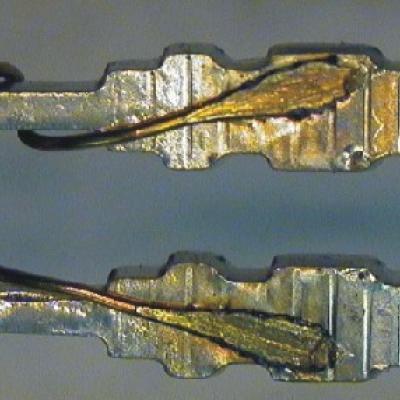

Using new and innovative technology can be risky, but it can often be rewarding. European electric-motor manufacturers Bosch, Siemens and Volkswagen realized this in 2011 after discovering hot crimping. For decades, these companies used machines or chemicals to strip the enamel coating off the ends of magnet wires before crimping them to copper ring terminals or sleeves. Hot crimping, in contrast, vaporizes the insulation during crimping of the wire and terminal or sleeve. By eliminating the stripping step, hot crimping enables manufacturers to increase productivity. . . .

Hot crimping technology features specially designed welding heads that quickly attach terminals to wire from 30 AWG to 350 MCM.

PROCESS HOT CRIMPING WINDING WIRES

USD900036S1 - Heater electrical connector and adapter - Google Patents

PROCESS HOT CRIMPING WINDING WIRES

Hot Crimping Magnet Wire

CN110652944A - Temperature controlled flange and reactor system

Hot Crimping for Joining Magnet Wires, 2012-04-02

55 Sets Servo Plug Male Female Connector Crimp Pin Cable Kit with

Hot Crimping for Joining Magnet Wires, 2012-04-02

Hot Crimping Magnet Wire

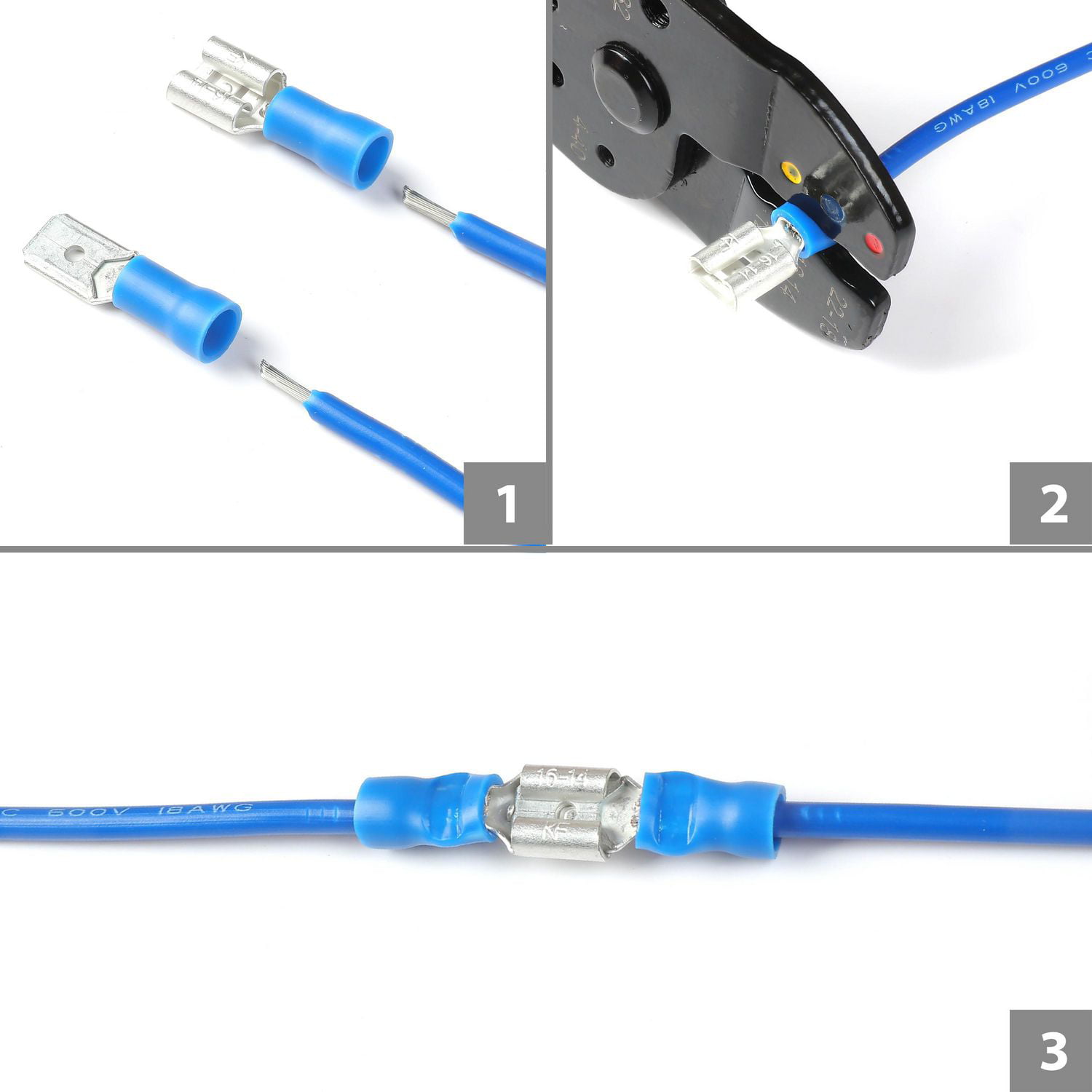

Hot crimping Connection of wires with cable lugs

Knipex Four Mandrel Crimping Pliers for DT Contacts Multi Component Gr

Hot crimping Connection of wires with cable lugs

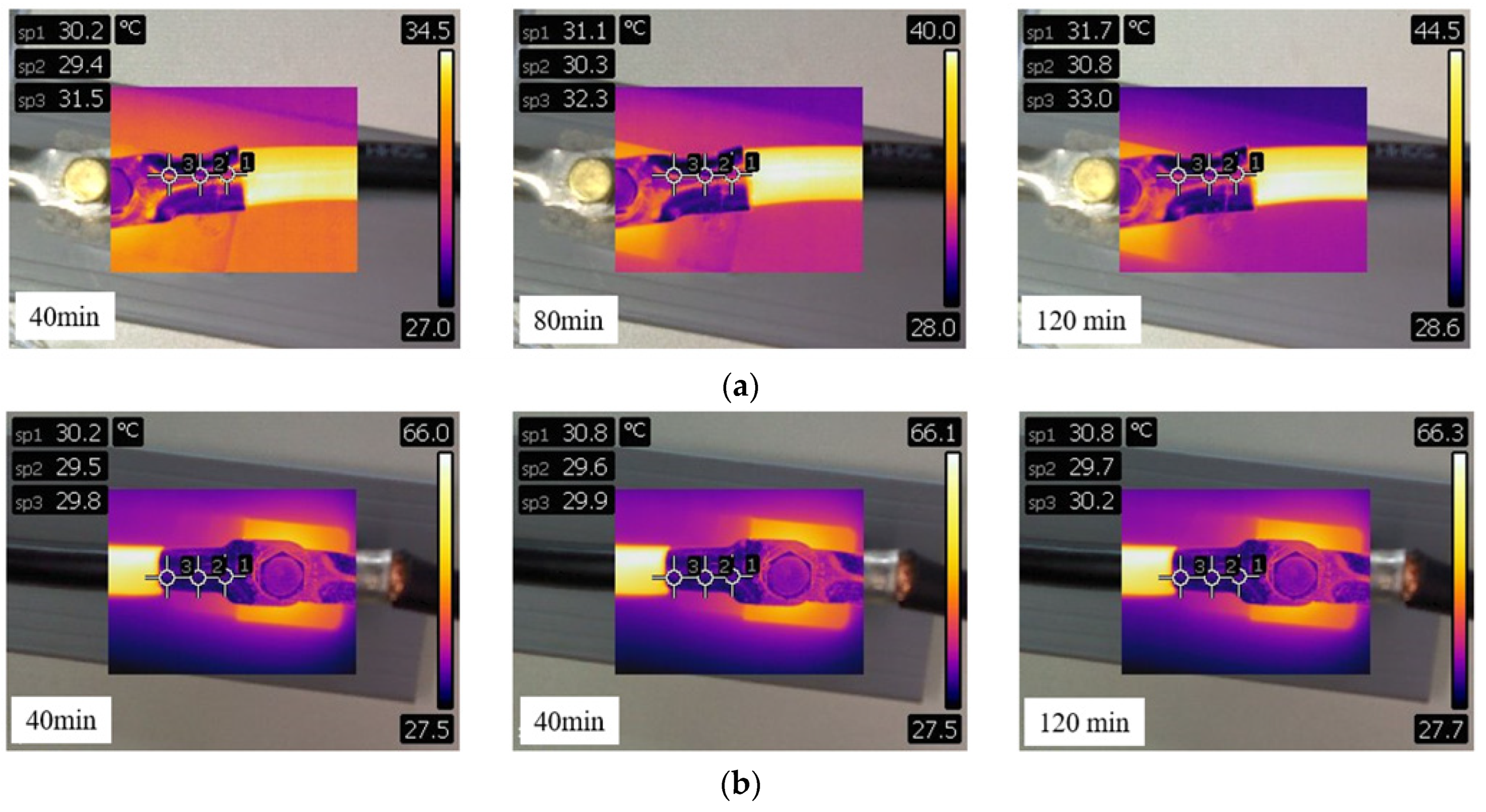

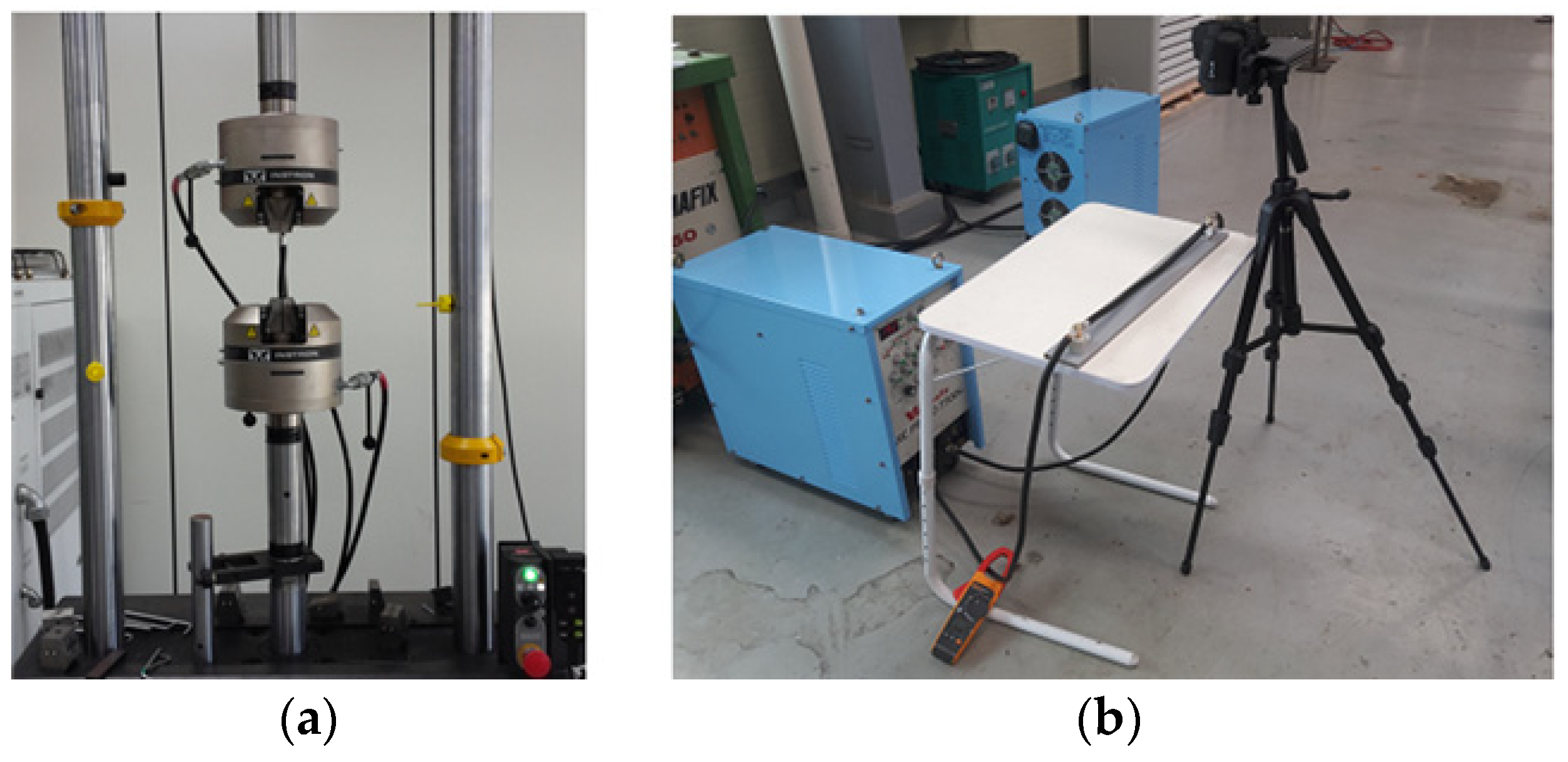

Metals, Free Full-Text

Metals, Free Full-Text