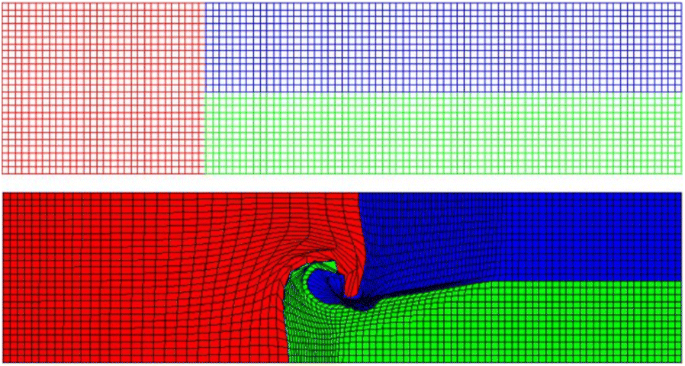

The FEM model for SSFSW process during the plunge phase: mesh of (a)

4.8 (159) · $ 6.99 · In stock

Download scientific diagram | The FEM model for SSFSW process during the plunge phase: mesh of (a) the workpiece and (b) the two parts tool from publication: Surface and mechanical characterization of stationary shoulder friction stir welded lap joints: experimental and numerical approach | Friction Stir Welding (FSW) is one of the most used solid-state welding processes in the aeronautical, aerospace, ground transportation and naval fields. Stationary Shoulder Friction Stir Welding (SSFSW) is a recently introduced variant of the process allowing lower heat | Friction-Stir Welding, Shoulder and Joints | ResearchGate, the professional network for scientists.

PDF) Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061

Gianluca Buffa's research works

Fracture surfaces of welds made under different processing

Strain distribution at the end of the refill FSSW process. (a) model

Progress in Thermomechanical Analysis of Friction Stir Welding, Chinese Journal of Mechanical Engineering

PDF) Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061

Micrografia de junta soldada de trilho intermediário atacado com

Finite element modeling of friction stir welding (FSW) on a complex curved plate - ScienceDirect

Two different finite element models investigation of the plunge stage in joining AZ31B magnesium alloy with friction stir welding

Micrografia de junta soldada de trilho intermediário atacado com

Material distribution at different plunge depths during FSSW of Al 6061

Skewness of the roughness profiles

Livan FRATINI, Professor (Full), Professor

FEM modelling of the three stages of friction stir spot welding - Gustavo E Carr, Nicolás Biocca, Guillermo A Lombera, Santiago A Urquiza, 2023